The mechanical watche (clock) is a very complicated mechanism. For its manufacture, in addition to machines, many more tools, attachments and accessories are needed. Optical and measuring devices, such as a microscope, a calipers, a micrometer and a measuring clock, also play an important role. Next are precise screwdrivers, tweezers, shtiheli, files, etc.

Rounding up tool

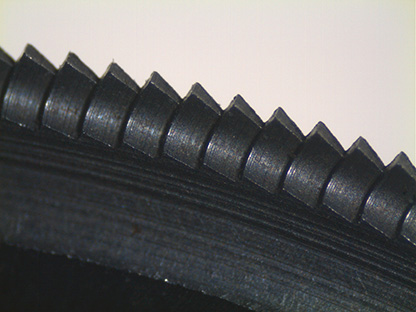

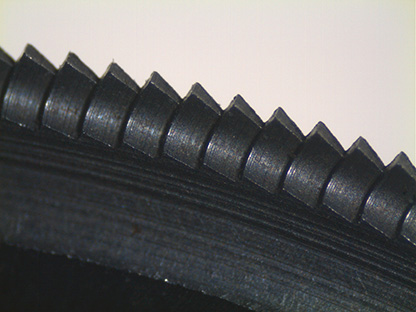

The gear-driven rounding up tool is necessary for correcting the tooth profiles of watch gears.

With it help you can correct many mistakes. For example, too deep a engaging if the teeth are too large, or the increased wheel, etc. However, there is some drawback - after the rolling, the teeth may become unequal.

The mills have a finely toothed profile on a segment two third of a circle, the rest is smooth. This segment serves as part of the spiral gear that engages the next gap between the teeth. When rolling, the wheel is scrolled by one division, thus the milling process remains uninterrupted.

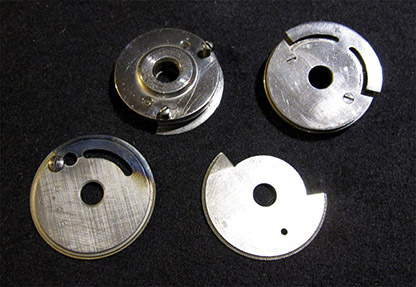

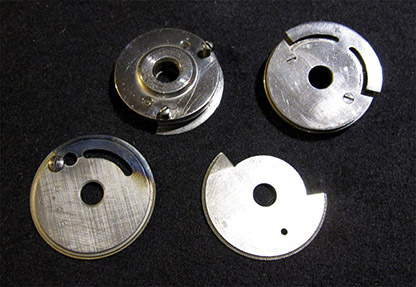

Staking and jewelling tool

Staking and jewelling tool is used multilaterally, for example, for the planting gears on pinions.

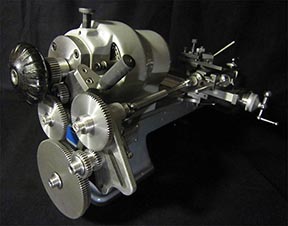

The Depthing tool

The depthing tool is used to set the distance between centers for a gear engaging a pinion. Each arbor is held on a pair of centers. The depth of engagement is determined by adjusting the screw on the front of the tool. To find the proper depth, the pinion is restrained slightly with one finger while the wheel is driven with another finger. By adjusting the depth and feeling the freedom rotation, a good depth can be established. The center points on the ends of the tool can then be used like reference point to note arcs on the watch plate.

Hairspring Balance Adjusting Tool E.Luthy-Hirt Bienne

To determine the length of the spiral, the Luthy-Hirt device is used. Basically, it consists of two parts: at the bottom - the reference balance, and at the top - exciting tweezers. The frequency of fluctuations in the balance can be adjusted from 10,000 to 22,000 vibrations per hour. The position of the tweezers can be changed in different directions: along the height, along the circle to the left and right, along the perimeter, forwards and backwards, and also rotate the tweezers itself around the axis.

The inner end of the spiral, as a rule, is fixed on the balance axis, the outer end is fixed in the tweezers of the measuring device. When you press the lever, both balances begin to fluctuate. By the frequency of the oscillations of the whole system, it is possible to establish whether both balances fluctuate synchronously or not. If not, then by shifting the fixing point, you change the length of the spiral to the desired one.

The number of turns of the spiral should not be too large or too small. To better calculate the turns, put white paper on the glass. In the case where the number of turns is already set, and the oscillation frequency is very different from the required one, you can try to pick up another spiral.

The diameter of the spiral should be in a certain proportion to the balance. If the number of turns and the diameter of the spiral has already been given, there are few parameters that can be changed. For example, you can choose a weaker or stronger spiral. The balance remains as a last resort. If it has bolts, then you can change the bolts or their position. But this is if you made the balance yourself. And if it is not made by you and you visually see that nobody has interfered till you in the balance, then it is better not to tamper it.

Of course, it is also possible to find out whether the spiral has the correct length on the basis of measuring the parameters with the help of a Mechanical watch testing stations. However, when fixing the pin, the spiral in this place is minimally deformed. Thus, if the deformation site is already far from the next fixing point, this will affect the quality of the spring.

The balance in the Luthy-Hirt is big and heavy, and the trunnions are very thin, in this case the goal is achieved the balance to fluctuate long. The trunnion supports do not have a shock protection and, therefore, the shipping of such devices is very problematic.

Although this device was created around the 1900s, it is used today to.

Watch Case Opener Rawyler