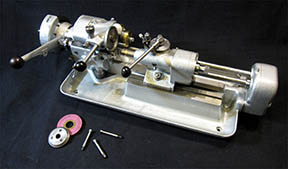

Pinion pollishing maschine Prata Type 11

Pinion pollishing maschine was produced by Prata in the Swiss city of Tavanes (Schweiz).The machine polishes the depressions between the teeth of the pinion.

The machined workpiece of the pinion, which came out of the CNC lathe, must be hardened and released. Then all the technical surfaces must be polished and perfected. The polished surfaces reduce friction. In addition, the polished surfaces are less prone to corrosion. The pivots must be rolled, as a result of which their surface is compacted. As a result, the pivots become stronger and more durable. In serial production, the pinions are polished mainly in tumbling machines. Because of this, the edges are rounded, and the surfaces are polished non-optimal. Therefore, for each work operation I use specially designed machines. They are not automated, so all is the manual work.

Pinion pollishing maschine was produced by Prata in the Swiss city of Tavanes (Schweiz).The machine polishes the depressions between the teeth of the pinion.

Thin sizing of the whole batch of the workpieces that are made on a lathe or automatic machine can be carried out with the highest precision on a Pivot pollishing maschine.