Black polishing on a tin plate, (Schwarzpolitur)

Polishing on a tin plate is a process by which a very smooth and even surface can be achieved. In this way, to perfect shine, you can polish only steel, certain properties of which contribute to this. Sometimes this method is also called the black polishing, because the surface roughness is so small that it can completely reflect light. At a certain angle, the polished surface becomes completely black.

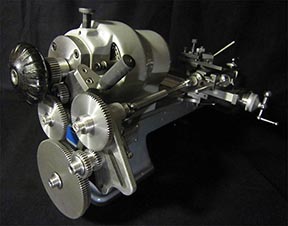

Parts such as bolts, levers and springs are attached to a tool for polishing flat parts. For this purpose, I prefer a sealing wax, which jewelers use, because in practice the remains of shellac are removed with difficulty. Sealing wax in seconds easily can be removed in an ultrasonic bath, with turpentine or gasoline.

First, the parts are grind on a glass with oil supply and a grinding paste, which is based on aluminum oxide. As soon as the whole surface becomes rough, you can actually start polishing on the tin. The tin plate is smeared a bit diamond paste, after that the part is polished in a circular motion. In this case, the material is removed from both the plate and the workpiece. Diamond paste becomes drier, and you need to grasp the moment when you increase the pressure on the plate and reduce the radius of circular movements. Then, try to raise the tool together with the part at the moment of movement, so that the part does not go beyond this polished radius and is not scratched again about the paste. At a grain size of 1 μm, polishing can be stopped. Do not confuse diamond paste with Diamantine. Diamantine is a paste based on aluminum oxide.

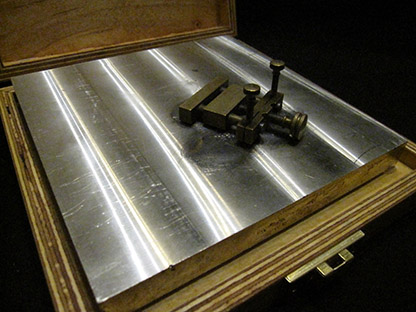

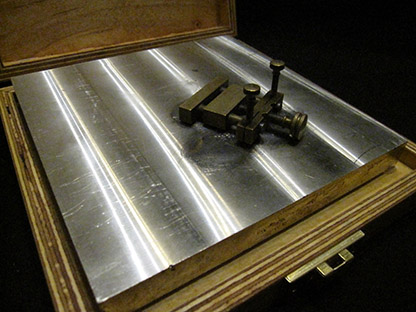

The most important thing during polishing is cleanliness. Work from a large paste to a smaller one. Glass or tin plate should only be used with one type of abrasive. When going to the next step, it is advisable to wipe everything thoroughly. Because one grain of coarse diamond paste penetrates into soft tin and scratches the polished surface. Washing the tin plate with gasoline does not give anything, since the diamond grains sit tightly in the tin. It will only help remove the layer of tin from the plate. The tin plates should be stored in separate boxes, well protected from dust and other unwanted particles.

The ready polished surface better not to touch . The slightest speck of dust on the gloves, rags and tassels can very quickly leave scratches.